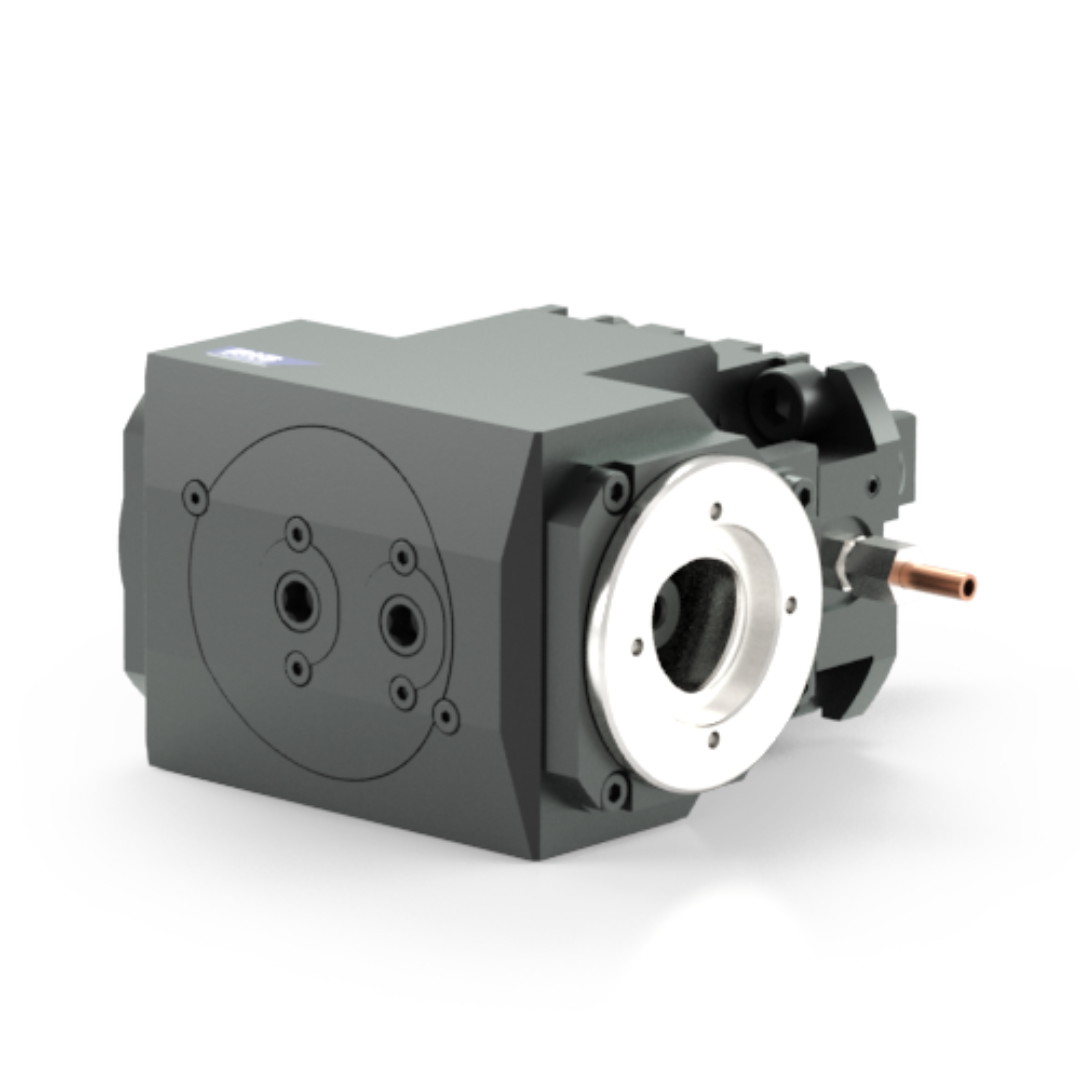

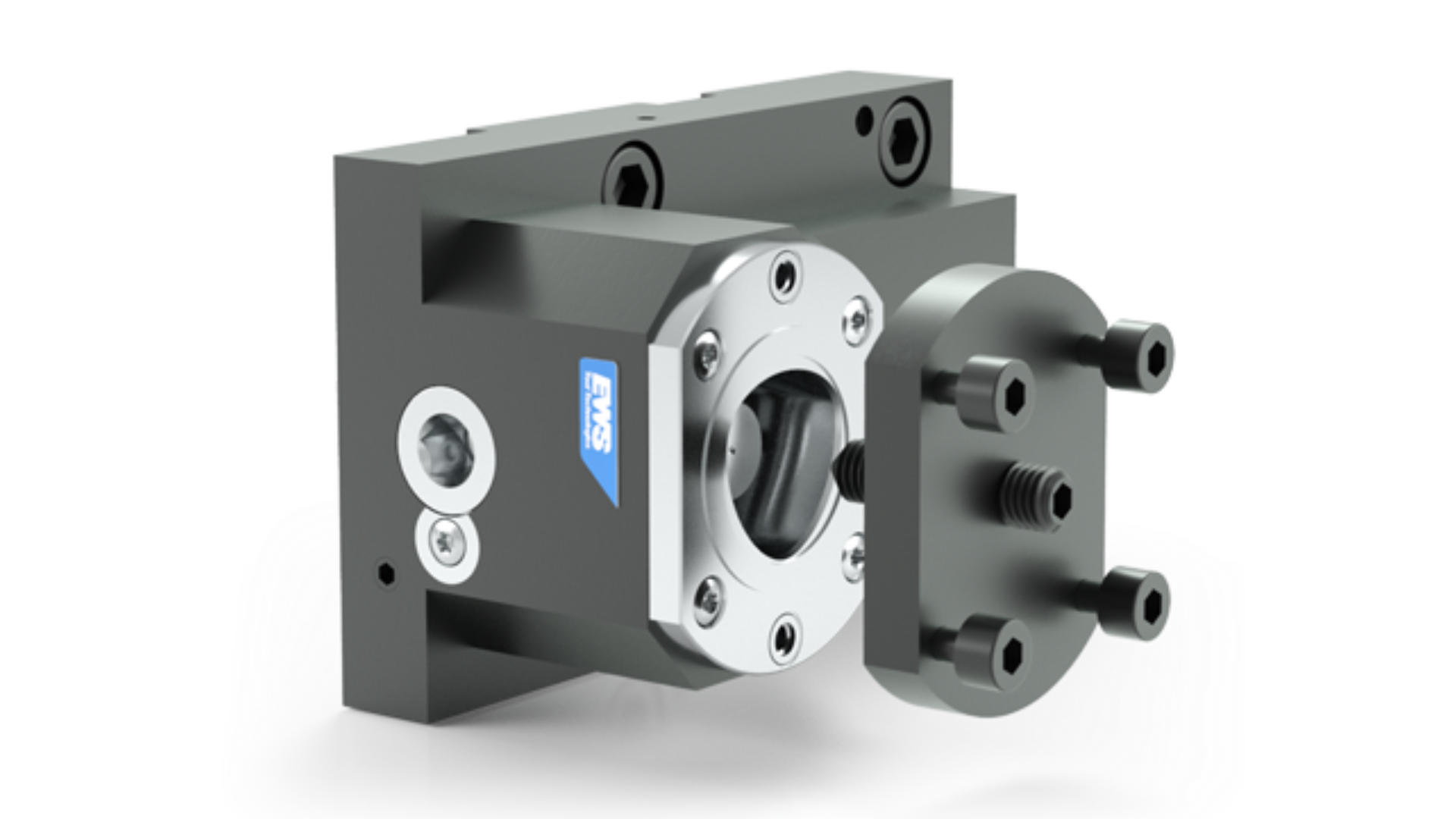

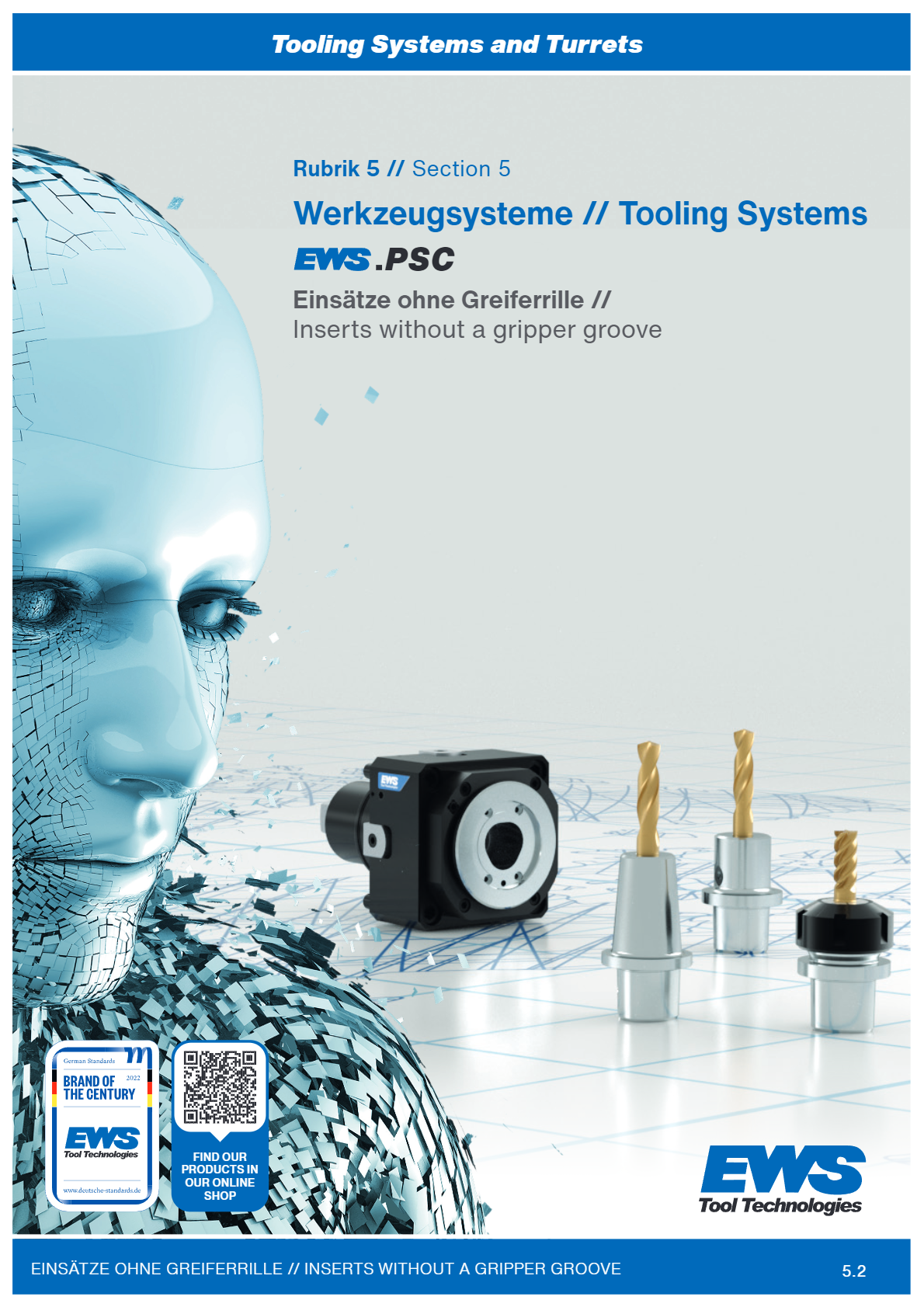

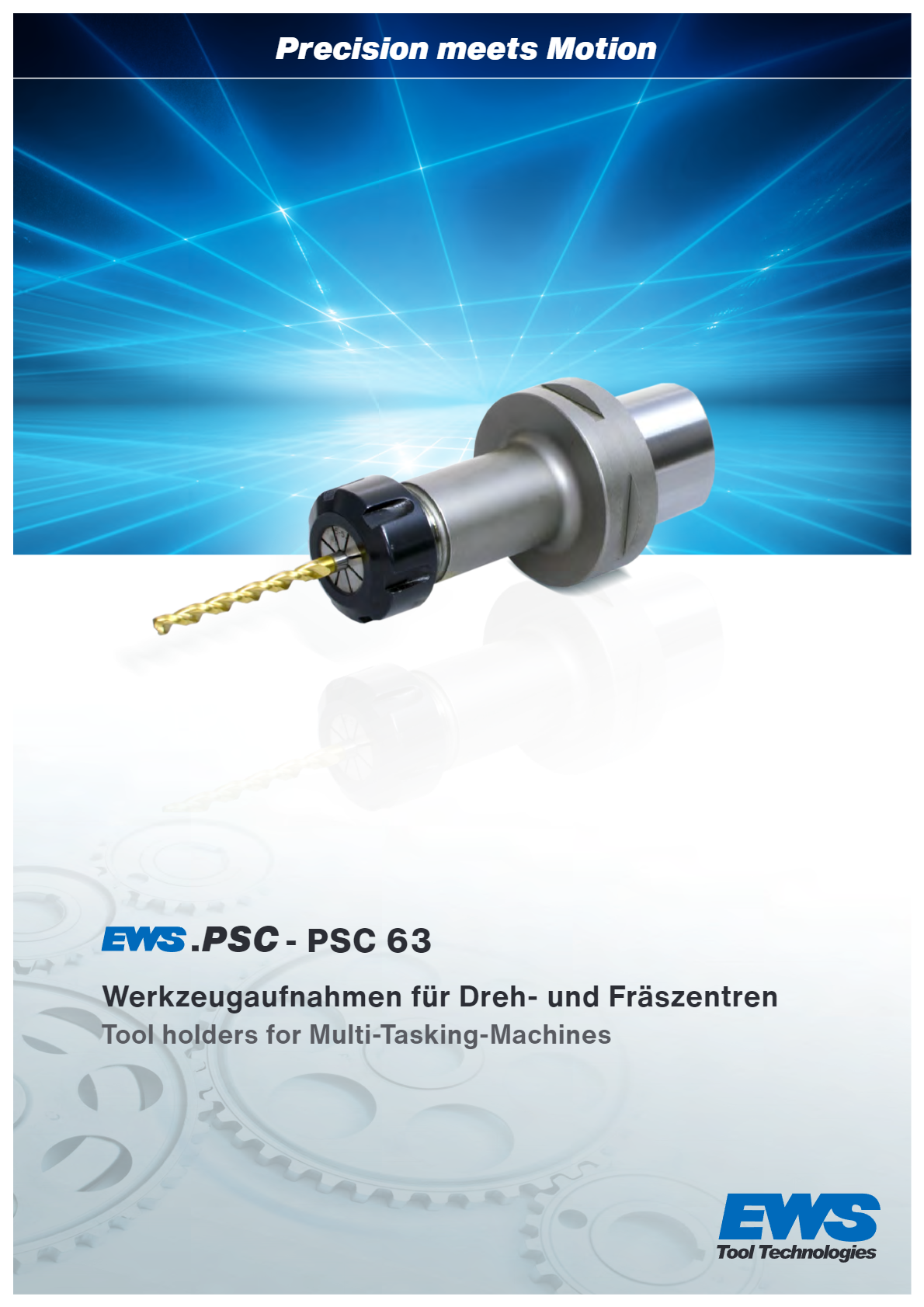

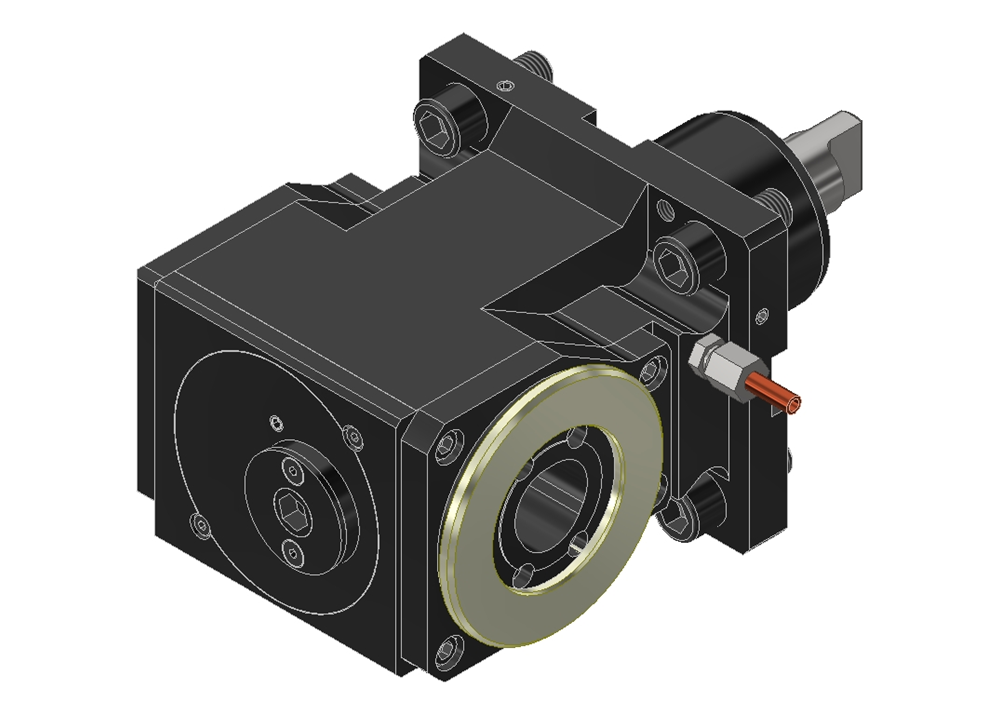

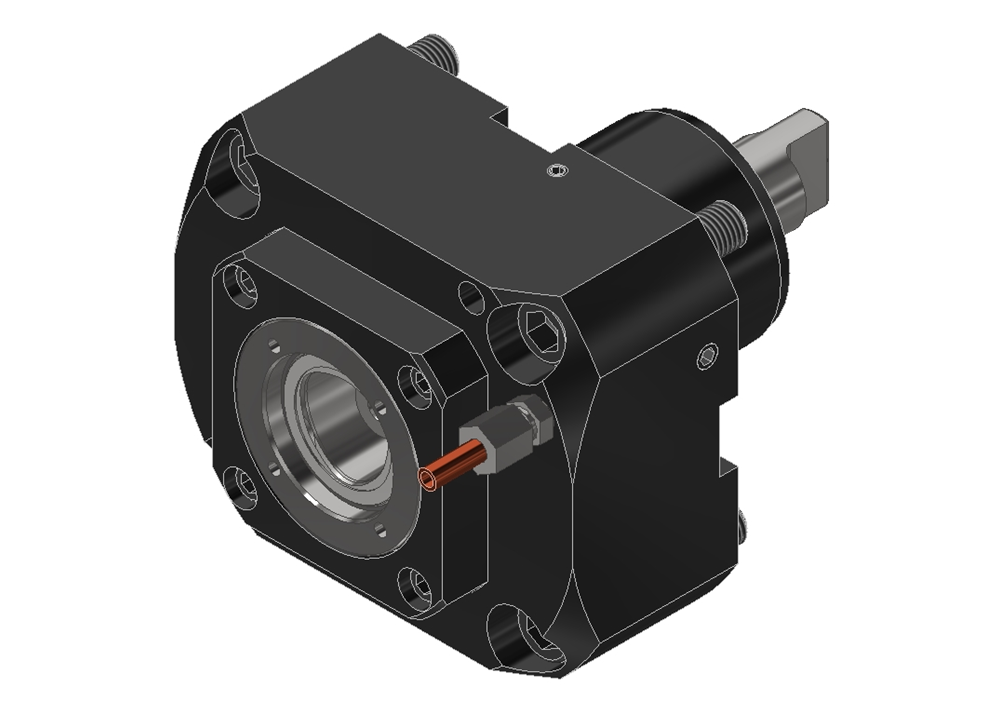

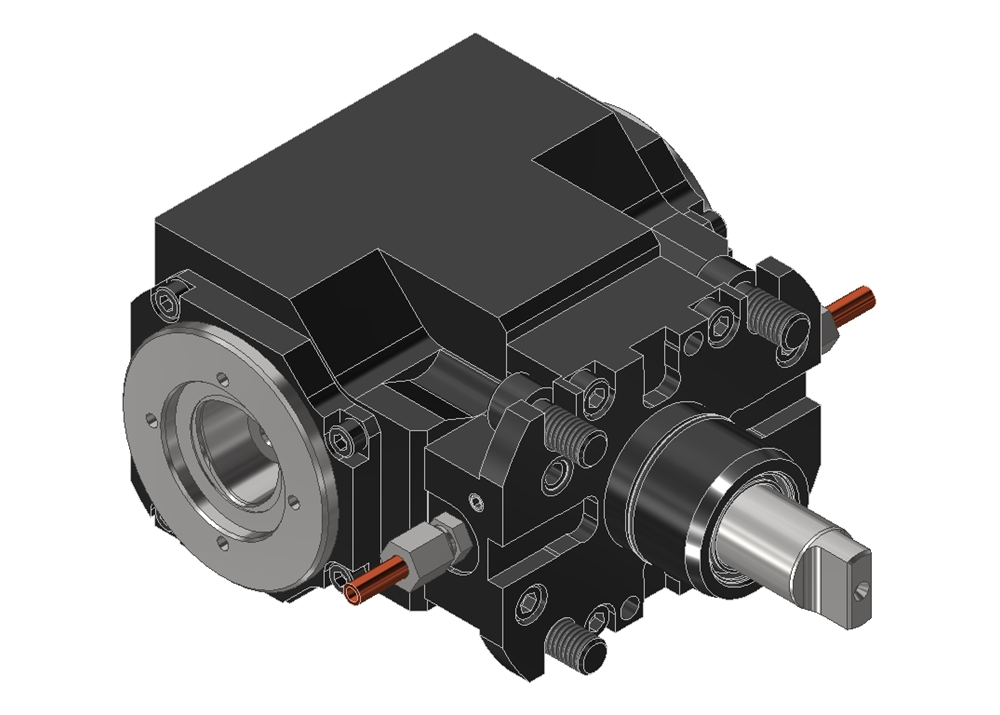

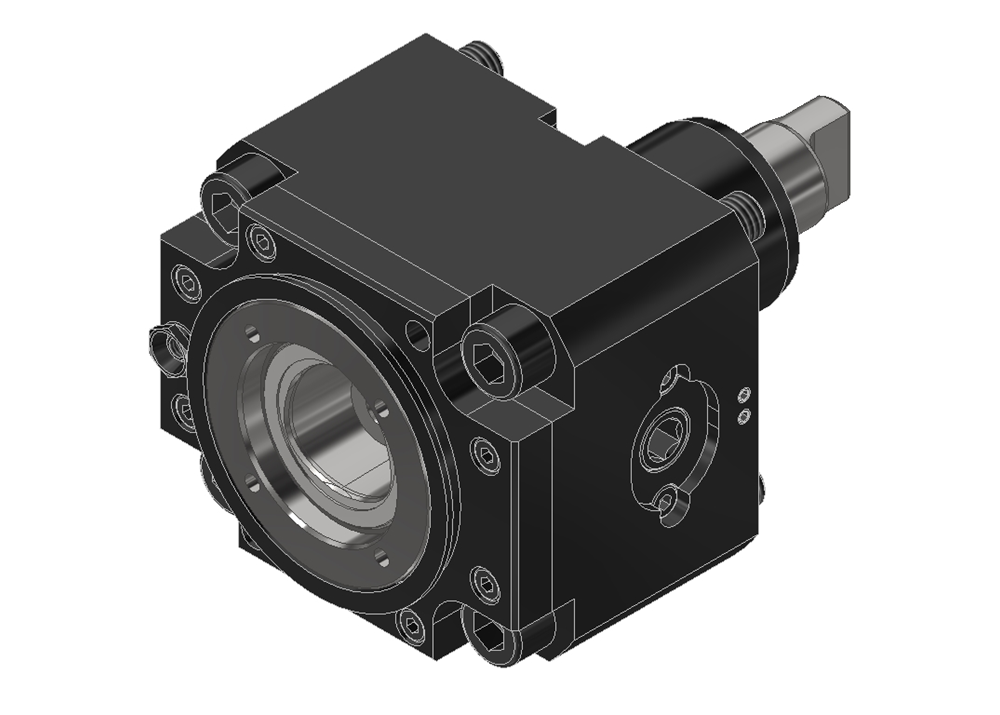

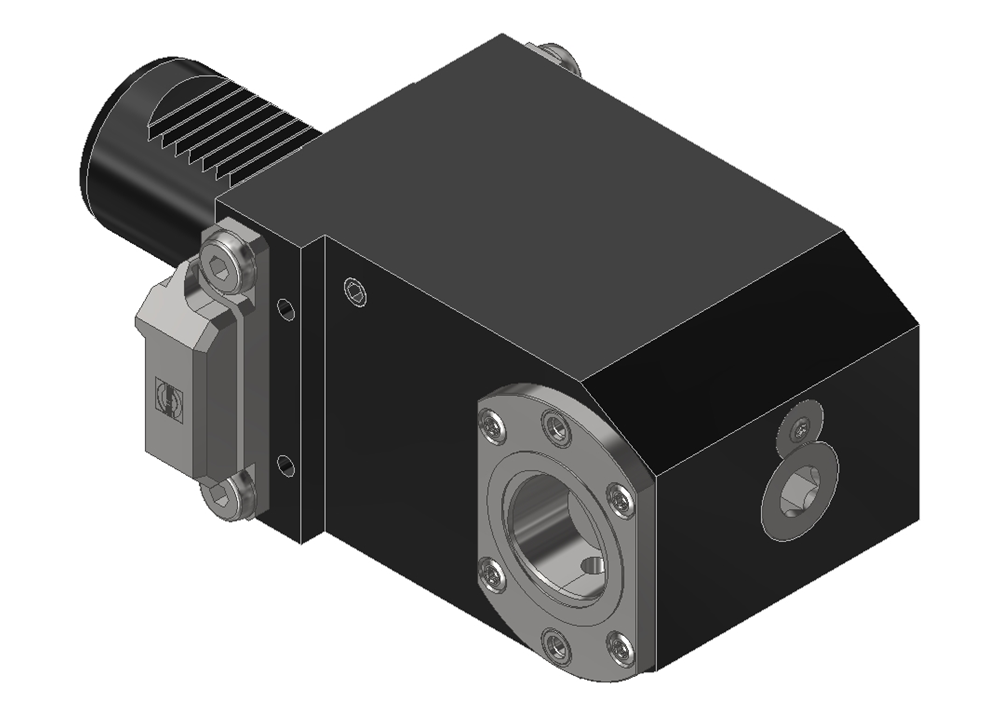

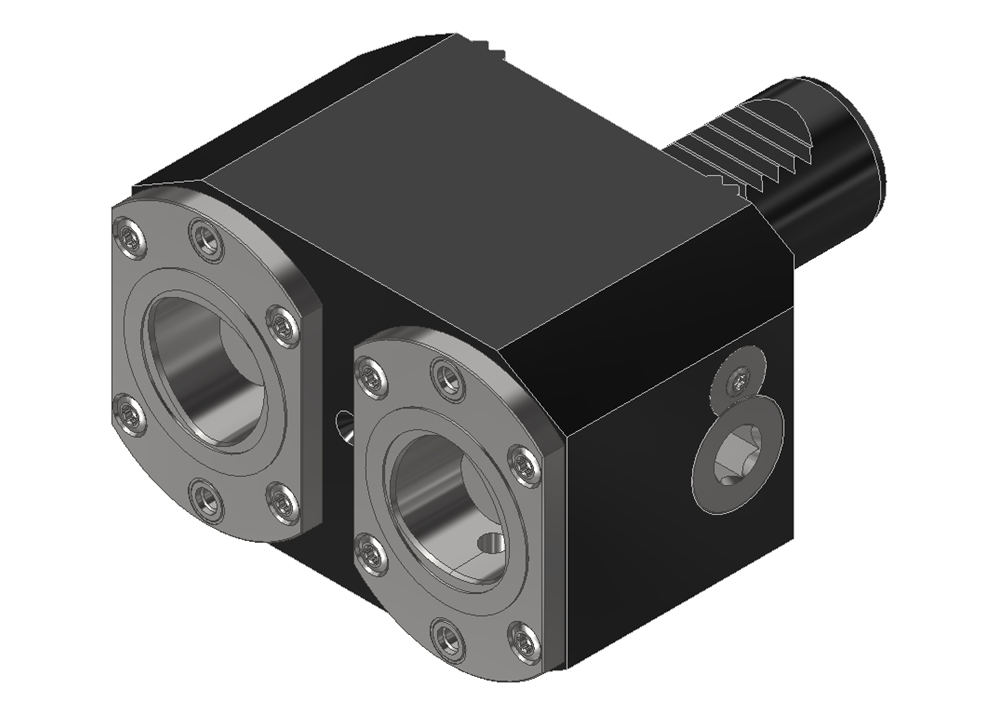

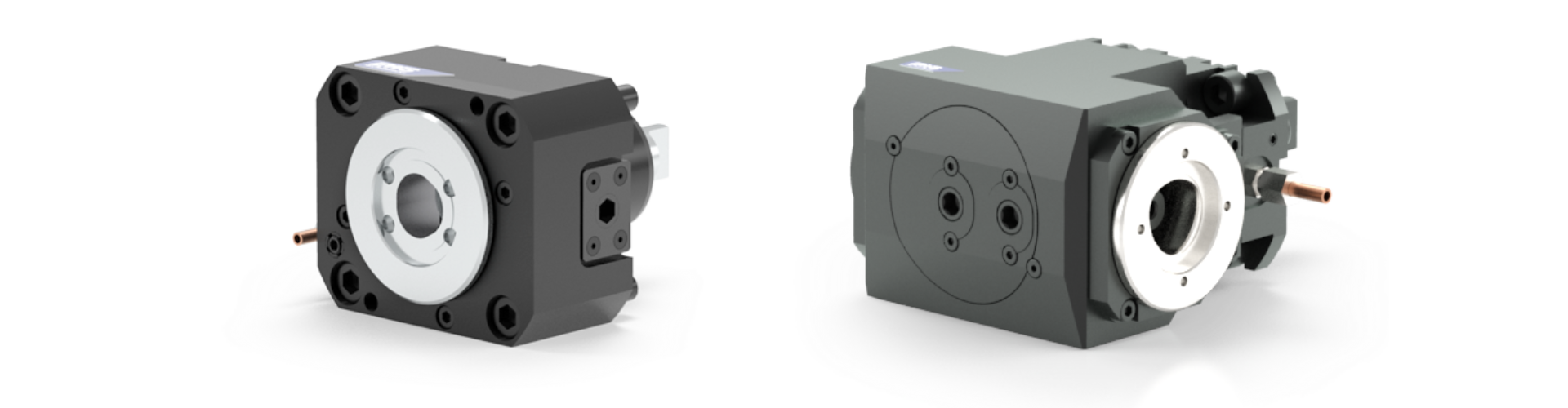

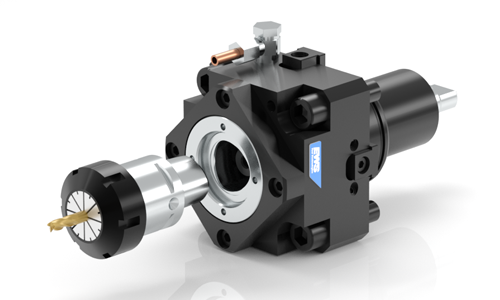

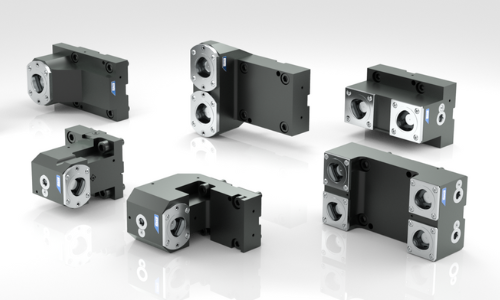

EWS.PSC offers flexibility and rigidity, combined with short set-up and changeover times for a wide range of interchangeable inserts.

This is the right choice for anyone who values a standardized changing system. EWS.PSC is compatible with products from market competitors.

.png)